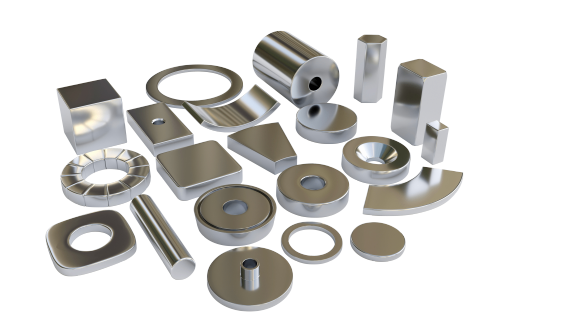

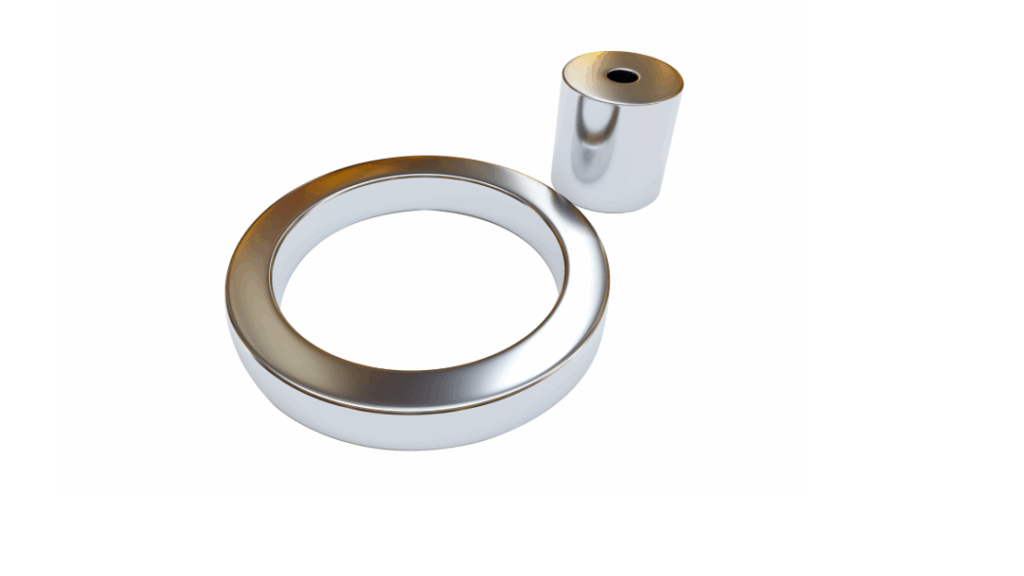

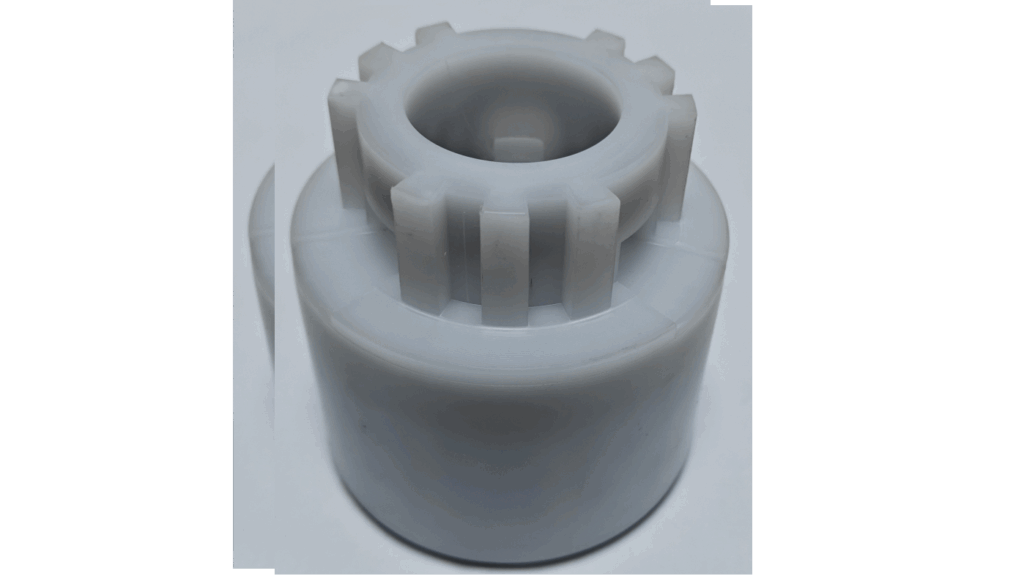

Injection molded magnets are manufactured through an injection molding process, typically combining magnetic materials such as NdFeB or ferrite with polymers. These polymers usually include thermoplastic materials such as polyamide (PA), polyphenylene sulfide (PPS), or polycarbonate (PC), which not only provide the magnets with mechanical strength but also enhance their heat and chemical resistance. Injection molded magnets are suitable for applications requiring complex shapes or precision components, meeting strict dimensional and functional requirements. They are widely used in the automotive, electronics, and medical device industries.