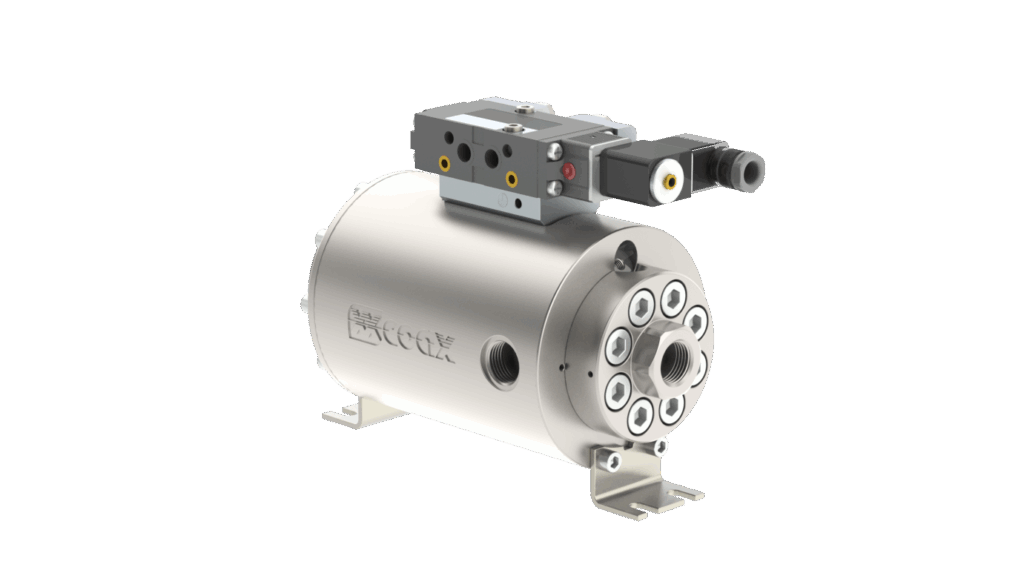

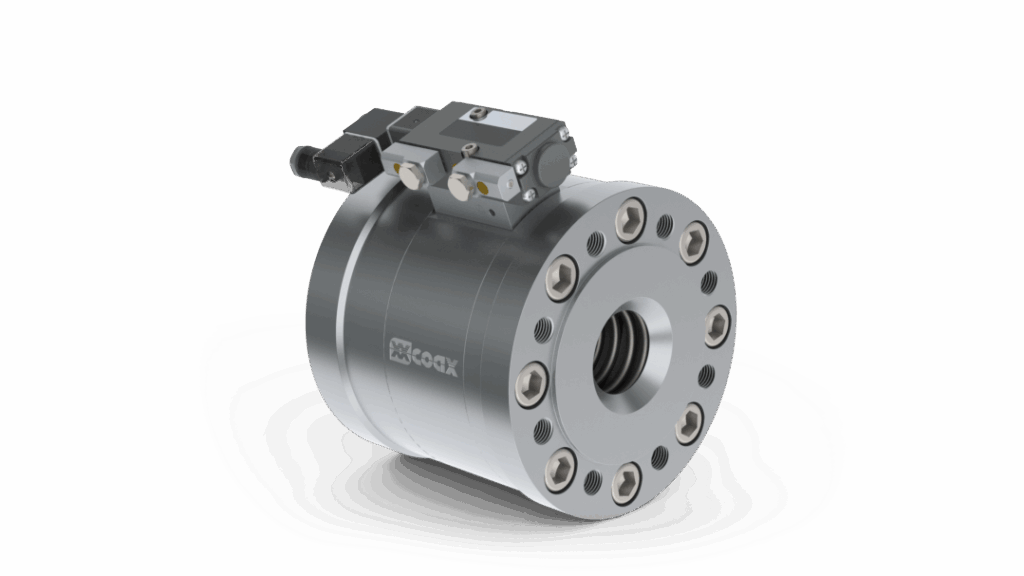

mmüller co-ax gmbh is presenting the latest version of the FMX series: The FMX 2.0, a valve with a very compact design and a high flow rate. With a new material configuration in stainless steel or aluminum and an improved pressure range of up to 40 bar, müller co-ax gmbh has developed a valve that can now be used not only with oil, but also with oxygen, hydrogen, ammonia, or methanol. This opens up new areas of application. The FMX 2.0 can now be used not only in machine and plant construction, but also in steam sterilization, vacuum packaging technology, and hydrogen applications, such as electrolysis.

The FMX 2.0 is characterized above all by its small and compact design and high flow rate. Combining these two properties is the ultimate in valve construction. As the inventor of the coaxial design, müller co-ax gmbh has a clear competitive advantage in this field. In this valve, the medium flows along the valve axis and opening and closing is achieved by axial movement of the valve tube. The valve is thus pressure-equalized and only the friction of the seal and spring force affect the switching process.

Regardless of whether vacuum or pressure is applied to the system, the pressure-equalized FMX valves save enormous amounts of compressed air and costs per stroke. Moreover, the valve size is the same regardless of the pressure level. The pneumatic valve drive is integrated into the housing in an extremely space-saving manner due to its coaxial position, which means that the valve is particularly suited to limited installation spaces.