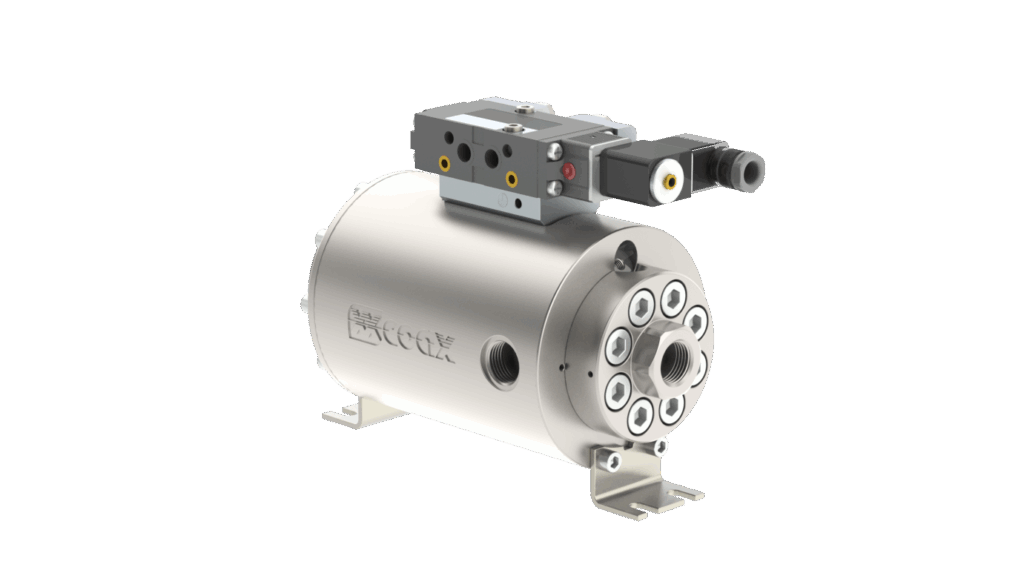

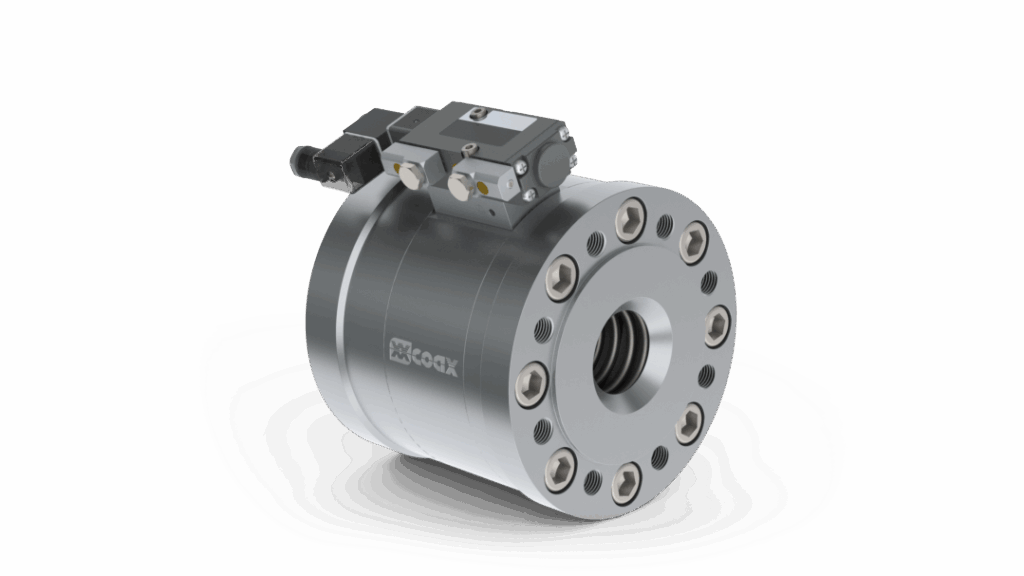

With the new Ex Solenoid Series D, müller co-ax gmbh introduces a consistently further developed generation of explosion-protected solenoid valves. The series has been specifically designed for safe operation in gas and dust hazardous areas and complies with the current requirements of the ATEX Directive 2014/34/EU as well as the international IECEx standards. Standardized voltage variants, increased temperature resistance and optimized thermal management set new benchmarks in terms of safety and efficiency.

The newly developed solenoid housing with improved heat dissipation, combined with a dual safety concept, ensures maximum operational reliability and long-term investment security for operators and plant manufacturers. A key feature of the Ex Series D is the availability of eleven standardized voltage variants from 20 V to 230 V for all nominal sizes of valves K10 to K50. This allows international control concepts to be implemented without additional modifications.

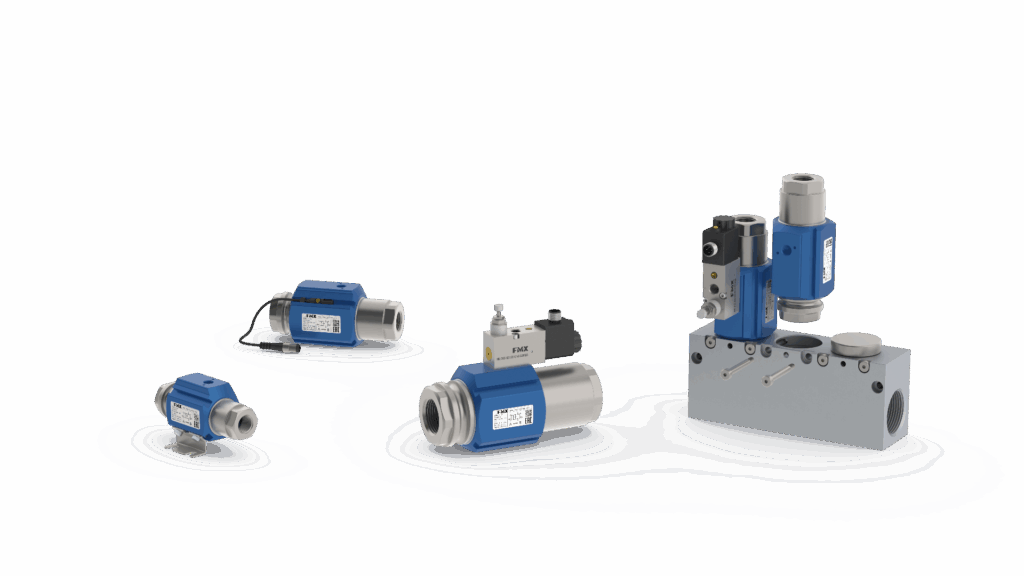

All valves of the Ex Series D are pressure-balanced, compact in design and suitable for both gas and dust hazardous areas. Modular mounting enables the reduction of valve spacing to just 30 mm, significantly lowering installation and assembly costs. ATEX and IECEx certifications ensure worldwide applicability.

The Ex Solenoid Series D is designed for demanding applications in the chemical, oil and gas, energy and process industries as well as in mechanical and plant engineering, representing the highest levels of safety, reliability and future readiness.