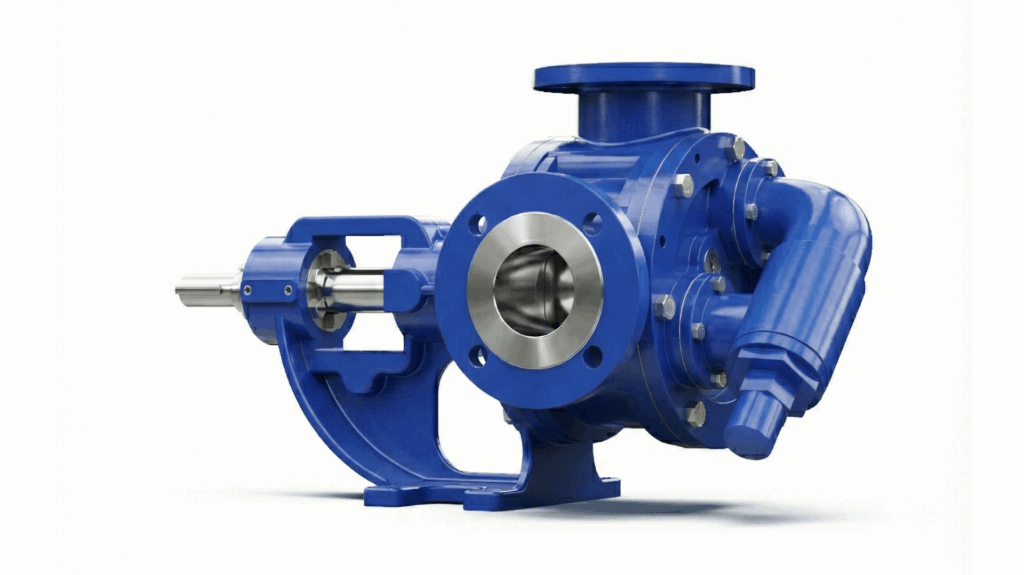

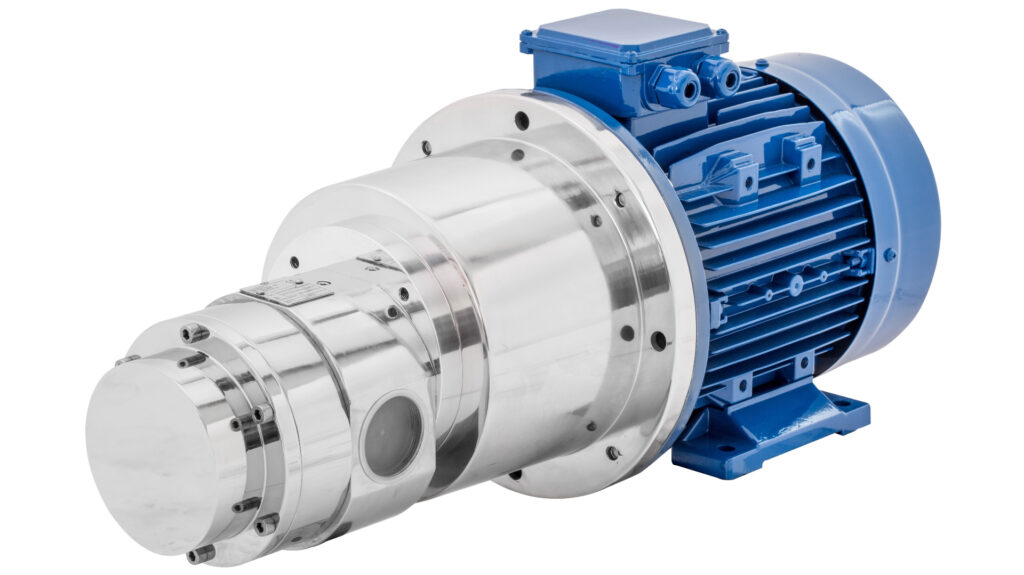

Internal eccentric gear pumps with magnetic coupling play a critical role in various industrial applications. These

pumps realize fluid flow in a continuous and controlled manner with the positive displacement principle, ensuring safe transport of viscous and abrasive fluids.

The magnetic coupling provides the sealing between the motor and the gear system. This prevents fluid from leaking out, minimizing environmental pollution and

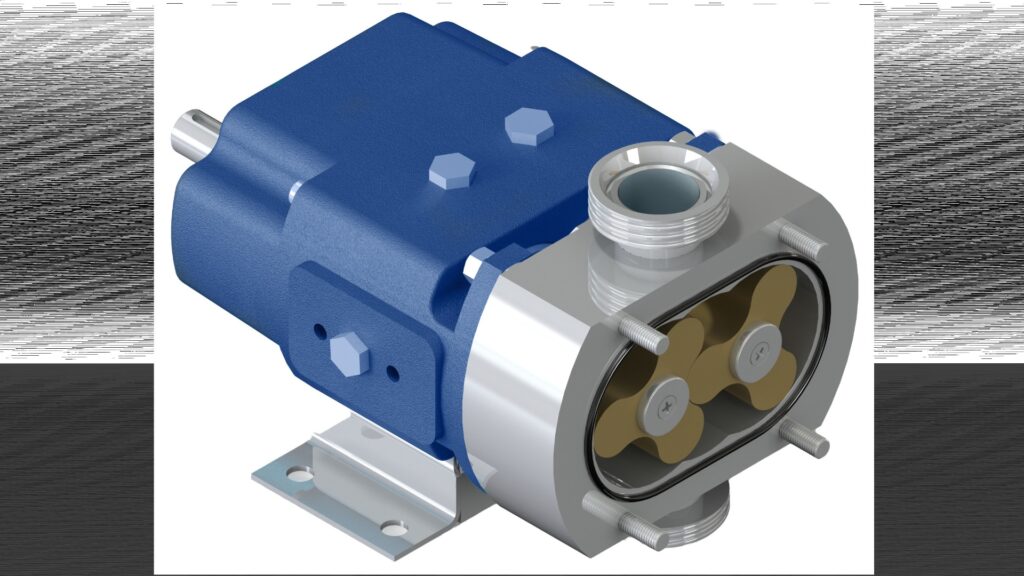

safely risks. By preventing leaks, the design prevents contamination of the fluid, which is particularly important in the food, chemical and pharmaceutical industries.

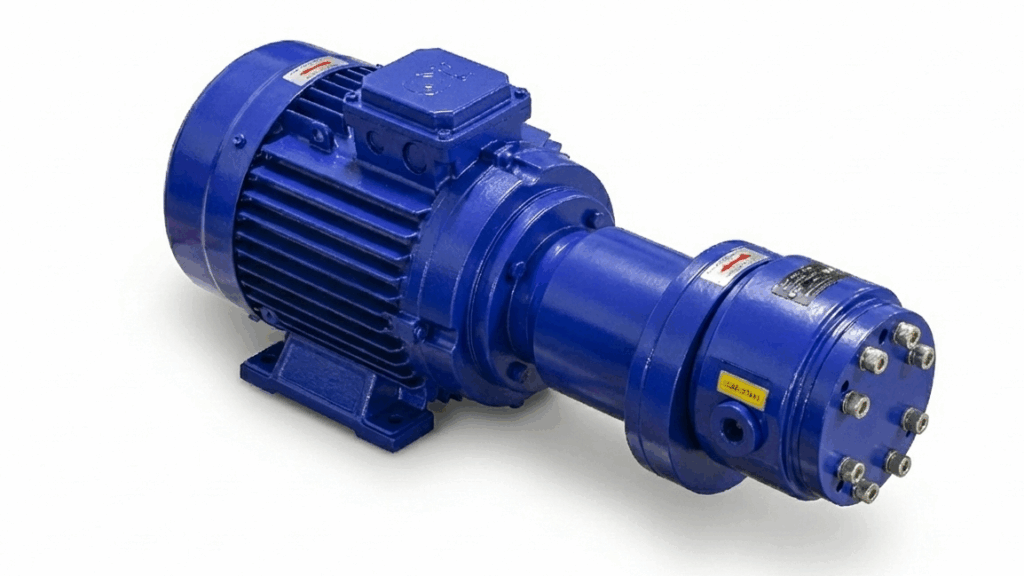

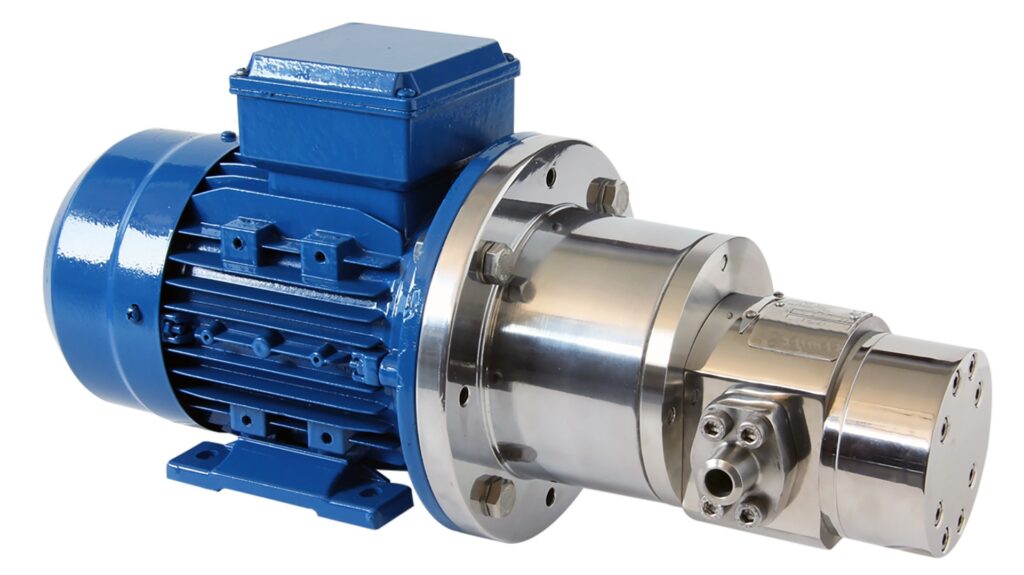

Pumps can operate at different speeds and pressures depending on the viscosity of the fluids. This offers advantages in applications requiring precise flow control.

Owing to the magnetic coupling, the absence of mechanical connection facilities maintenance and repairs. This extends the pump’s uptime and reduces operating costs.

By offering energy efficiency, it provides high performance with low energy consumption. This helps businesses to reduce energy costs.

They have a long service life owing to their structure resistant to harsh conditions. These features magnetic coupling internal eccentric gear pumps and ideal solution for applications requiring precise fluid transfer.