Green hydrogen, which is produced completely CO2 neutral, is essential for achieving the climate targets. The requirements on valve technology in hydrogen applications are considerable: high pressure ratings, higher flow rates, a high degree of tightness, durability, and ease of maintenance, to name just a few. müller co-ax gmbh, a leading manufacturer of coaxial and high-pressure valves, is presenting a hydrogen valve for pressures of up to 1,000 bar and a very high KV value.

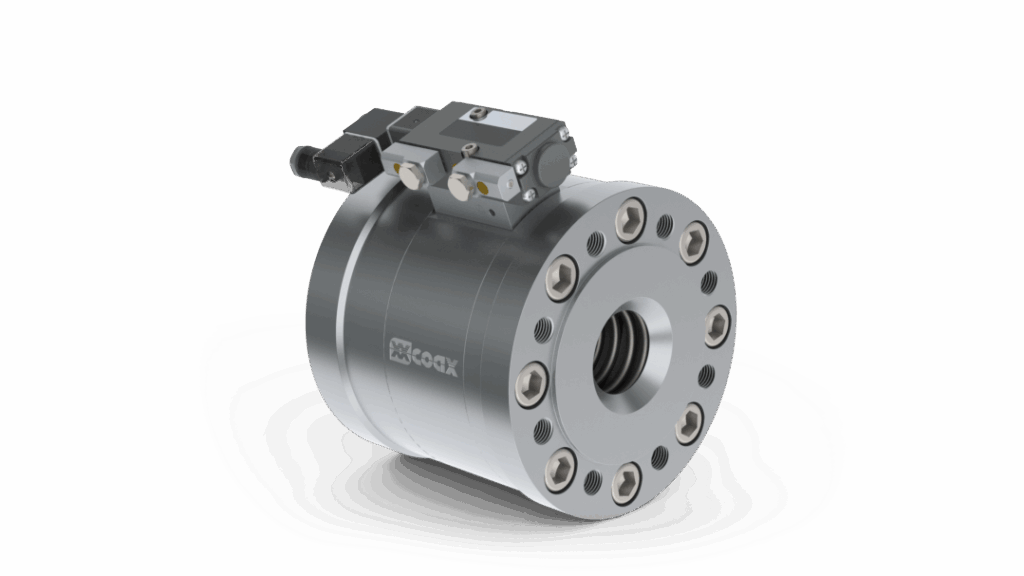

coax® valves offer an outstanding solution for the production, transportation, and distribution of hydrogen along the entire value chain. As they had to get more efficient in order to establish the existing solutions in the hydrogen industry, a new development was needed. With its new KX 1000 valve, müller coax is one of the pioneers, especially when it comes to handling high pressures and tightness with demanding media such as hydrogen. It is ideal for applications where a high flow rate, tight installation spaces, low weight, and low control air consumption are a particular concern.

Compact design with high throughput

Considering the high-pressure rating and flow rate, the KX 1000 is relatively small. The nominal seat width is 8 mm and the KV value is 1.9 m³/h. With an outer diameter of just 114 mm and a length of 205 cm, the valve weighs only 12 kg. The pneumatic drive is coaxially integrated within the valve and consumes only 120 cm³ of compressed air per switching operation. The end user benefits from significantly lower compressed air costs per year.