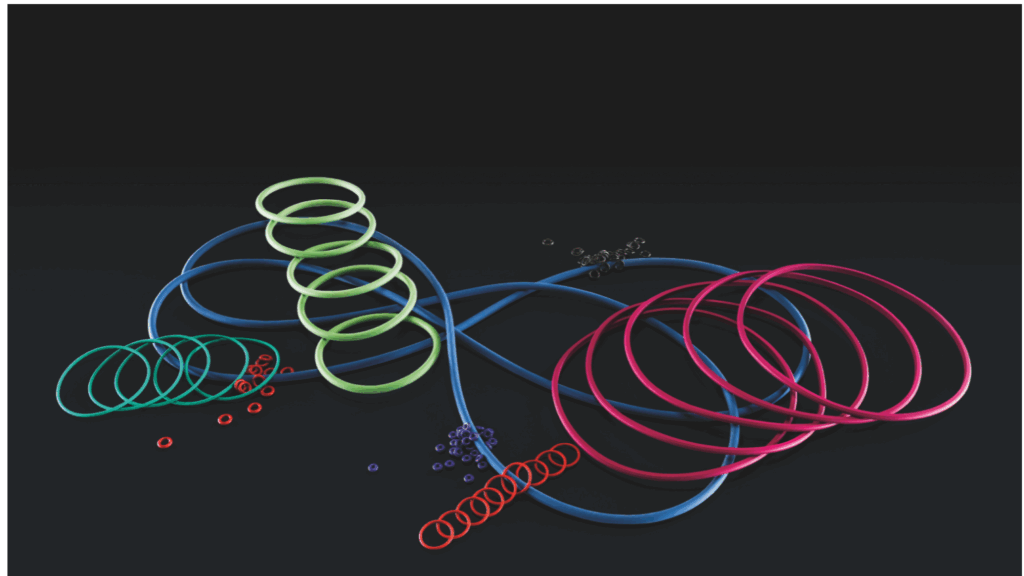

Cord rings are used in particular when suitable O-ring shapes are not available and the small quantity does not economically justify the production of a tool.

In contrast to compression-molded O-rings, cord rings are made from extruded cord and joined to any inside diameter by butt vulcanization – or, less frequently, by gluing. The butt-vulcanized version has become established because it offers physically better properties.

Nevertheless, the vulcanization point remains less mechanically resilient than with endlessly manufactured O-rings. Therefore, cord rings are not suitable for dynamic seals or for use in vacuum or gaseous media.

The result: economical sealing solutions for static applications – with individually manufactured diameters and controlled dimensional tolerance.

– Manufactured according to DIN ISO 3302-1, E2 (cord diameter) and L2 (extended length)

– Not suitable for dynamic seals or vacuum applications

– Alternative to O-rings for small quantities and special dimensions

– Stock items in NBR 70 black and FKM 75 black – E1 tolerance on request

– Tighter tolerances can be achieved on request